Gaz de schiste – les “secrets commerciaux” de l’industrie Translation by Ami(e)s du Richelieu, August 14, 2013

NWT fracking water license allows for company to keep ‘trade secrets’ by Meagan Wohlberg, August 12, 2013, Northern Journal

Alberta landowner and oil patch consultant Jessica Ernst says proper information on fracking chemicals and their impacts on human health and the environment is not being disclosed to the government, regulators or the public. The water license recently issued to ConocoPhillips for the first horizontal fracking activity in the Northwest Territories contains a legal loophole that should be cause of serious concern for the public, emergency responders and oilfield workers, according to critics. The license, awarded by the Sahtu Land and Water Board (SLWB) in June, requires the company to disclose all chemicals used while fracking with two exploratory wells south of Norman Wells, with the exception of those chemicals deemed to be “trade secrets.”

Under the license, the company must submit the name of each chemical ingredient listed on the material safety data sheet (MSDS) for each additive, along with the Chemical Abstracts Service (CAS) registry number from each chemical ingredient, to the land and water board within 30 days after each frac. But where the company considers the “specific identity of a chemical ingredient” to be a proprietary right, “a more general identification is to be used consistent with the MSDS,” the conditions of the license state.

According to Jessica Ernst, an oil patch consultant and landowner from Alberta currently engaged in legal action against Encana for allegedly polluting her community’s water through fracking, the incomplete list of chemicals being supplied to regulators, the public and emergency responders is putting the environment and human safety at serious risk. “If fracking starts to ramp up – and we have thousands of wells in Alberta – in terms of the first responders, how do you prepare your emergency people in hospitals and fire halls, medics, etc, if they don’t know the potential risks they may be facing?” she said. “The workers – why should the workers be exposed to chemicals that might be harming their health if they don’t know?” There is precedence for Ernst’s concerns. In 2008, an emergency room nurse in Colorado, Cathy Behr, nearly died after being exposed to a “mystery frac chemical” a patient was doused in. She lost her sense of smell and spent 30 hours in intensive care after her organs began shutting down. Although the company provided MSDS sheets to Behr’s doctors at the time of the incident, it refused to provide them with more specific information once she fell ill, according to news reports, meaning her doctor had to guess what to do to keep her alive.

More recently, responders to the train derailment and explosions that took place in Lac Mégantic, Que. were not told the oil in the tankers was fracked from the Bakken shale play containing chemical additives. That oil has now sunk to the bottom of the adjacent river, challenging cleanup efforts. “How can they properly protect themselves when they fight a fire or deal with a spill at an emergency if they don’t know what chemicals are in those tanks?” Ernst asked. “Never mind the people who live beside the site and are breathing the toxins.”

Ernst said workers and emergency responders in the North have more to lose when response and travel time is taken into consideration for emergency transportation. “You’re isolated up there in the Territories, so what if a worker is doused in toxic secret sauce and comes into emergency and nobody can warn any of the emergency staff how to protect themselves? They don’t know what kind of respirators to wear, whether to put him into isolation, whether other patients will be at risk from him dripping toxic chemicals into a hospital,” she said. “You have communities far apart, which makes it worse because a person who might be exposed would have to travel further and be exposed longer to get to a hospital.”

…

The leftover solution of toxic wastewater is either injected into underground storage tanks or, as ConocoPhillips plans, is hauled by truck to a dump site. The chemicals added to the mix include a range of solvents, gelling agents, friction-reducing agents and non-emulsifiers, among others, often listed by product or brand name or based on their purpose. For example, the list of chemicals and their MSDS sheets submitted by ConocoPhillips to the SLWB includes a “surfactant,” “breaker,” “water-friction reducing agent” and “X-CIDE™ 207 Industrial Microbiocide,” to name a few.

SLWB executive director Paul Dixon said the board gets information from companies in three ways: first, a list of all potential chemicals, then a risk assessment for those chemicals (to identify if there are less toxic alternatives available) and finally a breakdown of what was used after each frac. “Basically, there’s a couple different competing companies that run these fracking chemicals, and we get the breakdowns in the chemical MSDS sheets. So that gives us the materials found within each one of those frac fluids and where the frac fluids are commonly used,” Dixon said. “They disclose what they are, but then when they give us the list for what they used for that specific frac, the exact combinations aren’t given. They’ll give us the MSDS sheet – it will be all the chemicals within there, but the 0.1 or 0.2 per cent or whatever of this component or that component won’t be identified.” Dixon admitted that MSDS sheets can be “a little bit vague,” but still list the names of the products. “They’re not going to leave out a chemical, but some MSDS sheets are a little bit more well-refined than others,” he said.

MSDS sheets ‘a very good con’: Ernst

According to Ernst, information contained on these frac fluids’ MSDS sheets is incomplete, with some parts of the solution missing altogether. For example, X-CIDE’s ingredients only add up to 92 per cent of the fluid when using the max quantity of each additive (if keeping levels to the minimum, 38 per cent of the microbiocide is missing). For “Non-Emulsifying Agent W54” – an additive that contains naphthalene, a red blood cell destroyer, and which “cannot be made non-toxic” – four of the six components are listed as “proprietary” without CAS numbers disclosed. Ernst said part of the problem is the “trade secrets” loophole, but said the issue has to do with the MSDS sheets in general, which she called a “very good con.” Besides keeping trade secrets secret, by listing a generic product name like “corrosive” as the chemical itself, the sheets leave out what could be three to 500 harmful ingredients contained within, she said. “They (the board) are getting a number and a name and they think they’re getting a chemical,” she said. “But how much benzine is in each of those products? How much toluene – it’s a known neurotoxin that damages the brain, especially in children?…What acids are they injecting?”

Online disclosure sites like fracfocus.com, recently made mandatory in Alberta, also leave out specific information on chemical ingredients. A list of frac fluids on the website from one example well in Alberta gave no information on three of the additives; for the other four, only brand names were given, with no list of ingredients.

Complete list of chemicals unknown in Canada

An assessment done by former federal environment commissioner Scott Vaughan on fracking in February confirmed the lack of government knowledge on the chemicals being used. “Environment Canada and Health Canada told us that while a partial list of substances that are likely to be used in hydraulic fracturing has been developed, a complete list of substances used in Canada is not known,” he wrote, adding: “Environment Canada informed us that it takes about three years to establish control measures…Environment Canada and Health Canada told us that they are still working toward gaining a better understanding of the substances contained in hydraulic fracturing fluid and the risks associated with the hydraulic fracturing process.”

Ernst said regulatory boards and government are being “conned” into thinking they have the information needed to keep people safe and protect the environment, and should use the power given to them through the Canadian Environmental Protection Act to enforce full disclosure of chemicals, or prevent chemicals from being used until their health effects are studied.

“People have the right to know so they can make an informed, balanced, reasonable choice on whether or not they want to let this industry into their territory, or think of a better way to make energy,” she said.

“If people in the Territories knew that these wastes contained such and such chemicals and were radioactive, perhaps, had a certain concentration of carcinogens, neurotoxins, but the specific deadly chemical identified, I would expect communities anywhere who knew this would refuse to allow it.

“I don’t believe it’s at all about trade secrets.” [Emphasis added]

Health Effects of Chemicals Used in Fracking by Denise, Aug 12, 2013, Physicians for Social Responsibility – Los Angeles

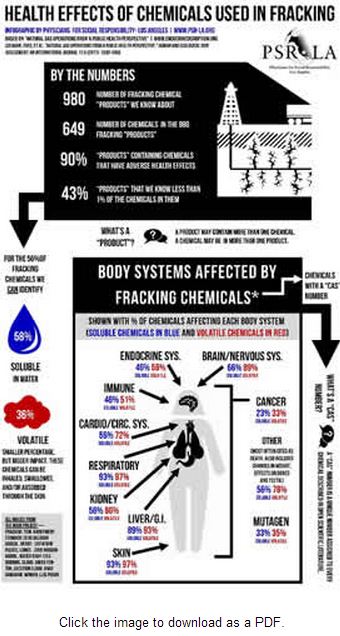

Many stages of oil and natural gas development use chemicals. These chemicals are used not only for hydraulic fracturing, or “fracking,” but also well drilling and during recovery and delivery of oil and natural gas. Many of these chemicals are toxic and may seriously harm human health and the environment. Surprisingly, a large number of the products and their chemical components used in the process remain undisclosed to the public because the oil and gas industry claims the chemical mixture is a “trade secret.” An in-depth review by Dr. Theo Colborn and colleagues at The Endocrine Disruption Exchange generated a list of hundreds of products used during oil and gas development and only a fraction of their respective chemical components. The study, “Natural Gas Operations from a Public Health Perspective,” published in 2011, presented an extensive database of fracking products and chemicals made publicly available to date, and their respective health effects. PSR-LA created an infographic to summarize what is known about the products and chemicals used in fracking and their known effects on human health and the environment. Click here to download the infographic (PDF). PSR-LA is committed to advocating for the public’s right to know about the chemicals related to oil and natural gas development.

Trade secrets v. public disclosure, Growth in hydraulic fracturing puts new pressures on oil industry by Alan Harvie, July 26 2013 issue, lawyersweekly.ca

Canadian governments, like many around the globe, face a conundrum. … The public disclosure of chemicals used in hydraulic fracturing, coupled with the desire to foster innovation by protecting trade secrets, is a recent example of the dilemma. …

…there is no doubt that some [chemicals] may pose a risk to human health or the environment. Consequently, occupational safety and health laws require companies to disclose hazardous chemicals on a Material Safety Data Sheet (MSDS). Material Safety Data Sheet reports had been required in the United States, Canada and elsewhere for decades. Therefore, energy companies in the U.S. had difficulty understanding why the public was demanding greater disclosure about fracturing chemicals than disclosed on an MSDS. If an MSDS was sufficient to protect workers, why was more disclosure required for landowners who faced far less risk? … These concerns led U.S. regulators to launch the “FracFocus Chemical Disclosure Registry” (FracFocus.org), a website where operators post information on the fracturing chemicals used at each well drilled. FracFocus.org contains records of the chemicals pumped into tens of thousands of U.S. wells. Regulators in Alberta and B.C. have followed some U.S. states in requiring public disclosure through the Canadian version at FracFocus.ca.

Canadian occupational health and safety laws require the disclosure of any hazardous products on an MSDS. Specifically, the federal Hazardous Products Act and the Controlled Products Regulations require suppliers of hazardous products to provide health and safety information on container labels and in MSDSs, including the chemical identity of the ingredients if it is over a specified minimum concentration. However, under the Hazardous Materials Information Review Act (HMIRA), trade secrets may be protected from disclosure on labels and MSDSs. Under the legislation, an applicant may file a claim with Health Canada for exemption of providing the chemical ingredient, its concentration and the name of any toxicological study that identifies the ingredient. An HMIRA registry number may then be used on the MSDS and label instead of disclosing the actual chemical or its concentration. In emergency situations, medical and emergency personnel may contact Health Canada to obtain the identity of the chemical.

British Columbia was the first Canadian jurisdiction to regulate the disclosure of fracturing chemicals. Under B.C.’s Oil and Gas Activities Act, a well permit holder must maintain detailed records of all fracturing fluids and post them to FracFocus.ca. For any ingredient that is the subject of a claim for exemption through the HMIRA, the HMIRA registry number may be provided instead of the name of the actual ingredient.

In Alberta, the Alberta Energy Regulator has requirements for well licensees to provide well completion data in order to maintain an accurate record of each well drilled in the province, including the chemicals used in fracturing. The regulator uploads some of the information to Fracfocus.ca and also allows for the protection of trade secrets through the provisions of HMIRA registry numbers.

[Cross check: Regulator Lawyer letter to Ernst: “However, the ERCB does not currently require licensees to provide detailed disclosure of the chemical composition of fracturing fluids.” ]

Although B.C. and Alberta’s adoption of HMIRA registrations for the protection of trade secrets for hazardous substances is efficient, difficulties remain for the protection of trade secret formulas for non-hazardous ingredients for which HMIRA registrations are unavailable. Today many oil and gas companies purchasing fracturing chemicals and services want “green” chemicals. This has led to significant research dollars being spent on green chemistry. One supplier has developed fracturing chemicals sourced solely from the food industry. Commonly, these non-hazardous formulations are the most valuable of all trade secrets. Alberta and B.C. regulators have therefore allowed non-hazardous chemicals to not be disclosed if a trade secret. Therefore, it is expected that numerous trade secret claims will be made for non-hazardous ingredients. When coupled with HMIRA registrations, the public may receive little useful information about the chemicals pumped beneath their land due to trade secret claims. It is expected that this dilemma of providing the public with information about fracturing chemicals and protecting trade secrets will not be easily solved. [Emphasis added]

[Refer also to:

A Toxic Spew: The near death- by frac chemicals – of emergency room nurse Cathy Behr collection of articles, 2008

Source: Legal Fractures in Chemical Disclosure Laws, Why the Voluntary Chemical Disclosure Registry FracFocus Fails as a Regulatory Compliance Tool by Kate Konschnik with Margaret Holden and Alexa Shasteen, April 23, 2013, Harvard Law School

FracFocus has ‘serious flaws,’ Harvard study says by Mike Soraghan, April 23, 2013, E&E News

Alberta joins British Columbia in partial disclosure of frac chemicals by Fracfocus.ca, January 1, 2013. Secrets permitted, e.g., for one of the 4 wells posted in Alberta so far, as of February 3, 2013, none of the chemical additives are disclosed:

Hydraulic Fracturing Fluid Chemicals, CAS#/MIRC# not provided

Dec 1 2012 – Dec 3 2012, 08-33-053-10W5, Artisan Energy:

CARRIER FLUID N2

CARRIER FLUID TG-740 Not Available

PROPPANT

ADDITIVE HB-4 Trican Breaker 0.46%

ADDITIVE HX-2W Trican Crosslinker 0.44%

ADDITIVE Hg-2 Trican Gelling Agent 0.46%

ADDITIVE S-12 Trican Surfactant 0.16%

Christa Seaman Policy advisor and lobbyist, Shell Canada Ltd. by Alberta Oil Magazine, August 14, 2013. She sat on the Canadian Association of Petroleum Producers’ shale gas committee when fracking fluid disclosures were made public in Alberta and B.C. – information that’s now readily available online (the information is found at fracfocus.ca). After earning a business management certificate from the University of Alberta, Seaman spent six years at Environment Canada, then two years as a co-ordinator at Canadian Natural Resources Ltd. She now advises Shell on its onshore shale operations, trying to strike a balance between environmental and economic concerns.